Oil Pump in Automatic Transmissions. Location and Functions. Problems and repair procedures.

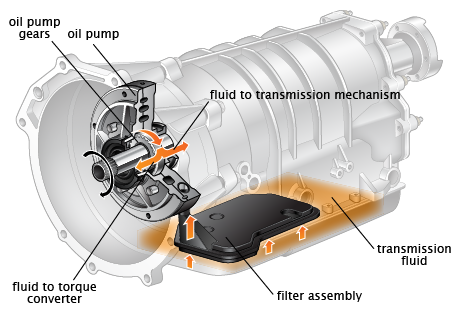

The car automatic transmission consists of numerous moving elements which require not only high-quality lubrication, but also efficient cooling. All this work is performed by the transmission lubrication system which is based on the transmission oil pump. This efficient transmission component helps to maintain the necessary system pressure and to increase the efficiency of lubrication with increasing RPM rate of the engine shaft.

Currently, automatic transmissions are equipped

with two main types of oil pumps:

-gear oil pump

-vane pump

Each of these types of oil pumps has its own pros and cons. Nowadays, most modern transmissions are equipped with advanced pumps that ensure optimal pressure maintenance inside the lubrication system.

The oil pump performs the following functions:

- builds up the main pressure for the hydraulic

control unit;

- generates oil pressure for the torque

converter with the purpose to prevent cavitation;

- flushing of the torque converter with oil to

eliminate heat;

- supply of oil under pressure to the hydraulic

control system as well as to the gear shifting elements.

Learn more about the

oil pump operation principle

The oil pump is inextricably connected to the engine shaft. It is designed to supply oil under pressure, which is used in the automatic transmission to perform numerous functions. In the process of operation, the oil pump is subjected to severe loads, therefore transmission repair specialists frequently have to deal with oil pump problems. These problems may manifest themselves in total non-operability of this component or pressure drop in the lubrication system. Modern automatic transmissions, equipped with numerous sensors, have the capacity for monitoring the system pressure that allows informing the car owner about problems with the pump. In many cases, the problem with the pump is solved by replacement of the faulty component.

Repair of the

automatic transmission oil pump

Symptoms of the pump failure

Problems with the oil pump in automatic

transmissions lead to insufficient lubrication of the transmission moving parts

and temperature increase inside the unit. As a result, there may be significant

problems with moving mechanical elements and consequent expensive and complex

repair. Thus, it is necessary to take seriously all symptoms of the oil pump

problems:

- jerks and kicks while shifting gears - that

indicates lack of proper lubrication in friction clutches

-issues with acceleration parameters

-gradual decrease of ATF level in the

transmission system

-noises which vary depending on the engine RPM

Therefore, it is recommended to visit the repair service when detecting any of the abovementioned symptoms in order to fix the problem with minimal costs.

Reasons of the oil

pump malfunctions

Generally, the oil pump failure may be caused by the following reasons:

- Installation of the transmission is performed

incorrectly (wrong size of the end clearance);

- The ATF level is too low;

- Intolerable operation conditions (clogged

mesh oil filter, high suction of intake pressure). It is also notable that the

oil pump failure may be caused by misuse of the car during the winter season.

Quite often, car owners do not warm up the transmission fluid, but start moving

without any warm-up. As a result the oil does not have the proper viscosity

status that leads to an excessive load on the oil pump. The oil pump rapidly

fails to function under the influence of such loads.

- Rapid wear of the pump due to the aggressive

driving style with abrupt accelerations and braking;

- Poor oil quality (rapidly becomes

contaminated or does not correspond to current specifications); during

operation, particles of settle down on mobile parts of the pump. This debris

clogs pore spaces of the pump and puts it out of order. Frequently,

transmission specialists have to deal with oil leakages caused by issues with

seals or bushings;

- Disregard of the main car performance parameters (in particular, oil pressure).

Example of the oil

pump damage

Scuff marks and scratches that appear during

long operation of the transmission have a bad impact on the operation pressure

maintenance, and as a result, badly affect performance of the automatic

transmission. Therefore, restoration of working surfaces of pumps in automatic

transmissions is a top-priority task to prolong the service life of the

transmission.

In many cases, the oil pump replacement is a

more reasonable measure than its repair. Although this step is more expensive it helps to rule out

the possibility of failure of other automatic transmission units due to

improper operation of the pump.

Oil pump location

The automatic transmission oil pump is located

inside the gearbox, so when transmission specialists have to deal with the oil

pump issues they have to tear down the transmission and remove the bellhousing

from the transmission. When performing these operations it is required to take

into account the design peculiarities of each particular car and specific

modifications of automatic transmissions. Therefore, it’s better to leave this

tricky task for experienced specialists who can quickly determine the oil pump

location and perform all necessary repair procedures in the shortest possible

time.

Oil pump disassembly

But if you nevertheless decided to examine the

oil pump and fix minor issues by your own efforts, then it is necessary to have

all necessary instruments at your disposal (screwdrivers, metal ruler,

dipstick, indicating gauge, etc.). First of all, it is necessary to remove the

protective cover (bellhousing) of the automatic transmission. It is required

to take into account the design peculiarities of your car and the automatic

transmission model. It can so happen that you don’t need to tear down the

transmission to examine the pump.

It is necessary to know the main components of

the oil pump: inner gear (driving), outer gear (driven), O-ring, bushings,

rotary shaft, and fastening bolts.

To check if there are any flaws on the pump body,

shift the outer gear, measure the clearance with the help of the dipstick and ruler.

If the clearance is more than 17 mm, the oil body must be replaced. For more

thorough inspection and replacement of defective pump components, it is

required to disassemble the pump. Firstly, you will need two screwdrivers to turn the inner pump gear,

unscrew bolts, and remove the rotor shaft. Then remove both pump gears, and if

there are visible defects, replace them with new ones. It is sometimes the case

that the oil pump bushing gets welded to torque converter hub and damages the

pump body. Therefore, make a careful examination of the bushing, measure

bushing diameters of the body and shaft with the help of the indicating gauge.

The maximum permitted values are the following: body bushings – 38.18 mm, shaft

bushings – 18.5 mm. In case of deviations from the abovementioned body bushing

standard, it is necessary to replace the body itself. Consequently, in the

second case the shaft must be replaced.

Informative videos

about the oil pump removal and disassembly

Oil pump assembly

After the examination and repair procedures, it

is necessary to assemble the automatic transmission oil pump. The assembly is

performed in the following order:

-Install the inner and outer gears in the pump

body one-by-one;

-Adjust the shaft to the holes of fastening

bolts;

-Screw in bolts and carefully tighten them;

-Make sure that the inner gear does not stick

when rotating.

That’s how the oil

pump of Z F5HP19 is assembled

There is no general instruction for repair of the automatic transmission oil pump, because each car has its own design peculiarities. Modern cars may differ in the oil pump location, arrangement of parts as well as their number and shape. Therefore, if you are not sure that you can independently deal with the oil pump problems, then it’s better to leave this task to the professionals.