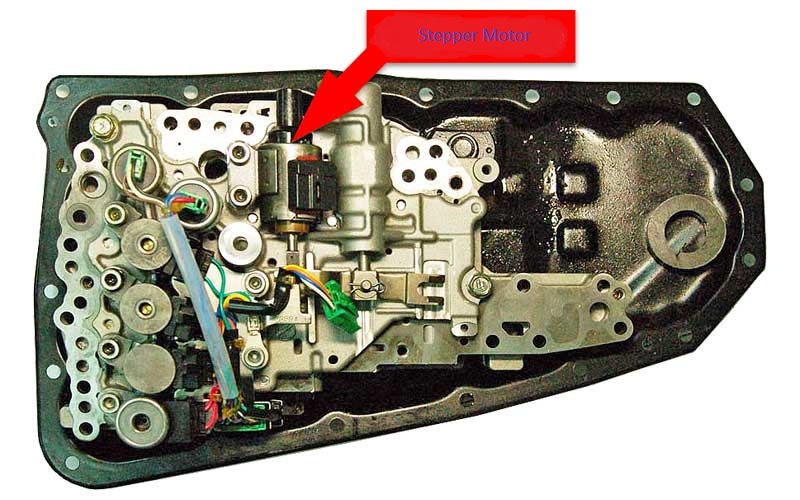

Stepper Motor in CVT. Functions and Typical Problems

Continuously variable transmissions (CVT) made a true revolution in the world of automotive industry. With the course of time, transmission engineers came up with a wide range of unusual design solutions for CVTs. However, CVTs weren’t used widely due to lack of synchronization between the driving shaft and other internal parts. This issue led to cutting of gearing teeth, lack of alignments, and complete wedging. This major problem was solved with the help of the stepper motor specially designed for CVTs.

Stepper motor

functions

As it has been mentioned above, the

stepper motor is intended for synchronization of gear ratio of the pair of

cone-shaped pulleys by increasing or decreasing the distance between them. A

standard stepper motor is an

asynchronous electric motor (induction motor) without any brushes.

The

peculiarity of this motor lies in the fact that the complete shaft revolution

can be divided into particular number of specified equal steps.

Stepper motor in CVT JF011E

The stepper motor operates jointly

with the valve, controlling the gear ratio. This valve ensures 3 basic states: filling

in, backup, and release. The hydraulic fluid pressure determines positions of

pulley cones in CVT. In response to driver’s actions, the electronic control

unit (ECU) sends a signal forcing the stepper motor to move and changes

position of the control valve. Driven pulleys move due to the effort created by

the belt (or chain), while driving pulleys are moved by the stepper motor.

Informative video about CVT Stepper Motor

The gear ratio can be reduced due to the fact that the valve goes into pressure release mode for only half of the stepper motor revolution. In this case, sides of the pulley come apart and the whole system switches to transmission mode with the highest torque (gear ratio reduction). In the process of driving these cycles repeat constantly up until the unit failure.

Typical problems

The most typical problem, occurring

in the stepper motor, is the winding

damage. Usually transmission specialists recommend replacing this element

together with oil change and replacement of all filter elements. In many cases,

repair specialists have to deal with the broken pawl of the stepper motor. This

pawl controls the position of pulleys via the load valve. When it gets out of

order, the gearbox will get stuck on one gear. The stepper motor repair should

be performed only by professionals, therefore it’s better to visit the nearest

workshop when having any problems with the stepper motor.