What is the use of Viscous Coupling Unit in AWD Cars?

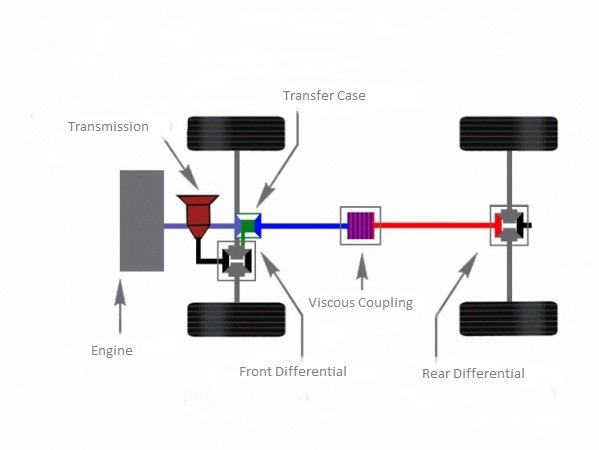

The Viscous Coupling (VC) is the transmission component intended for transmission and leveling of torque from the center drive shaft to the front differential, and on to the front wheels. In contrast to the hydraulic coupling and torque converter, the VC uses a different operating principle: torque is transmitted not through dynamic properties of fluid flow, but thanks to viscous properties of the fluid, which fills the internal space of the viscous coupling unit. This unit is used as a mechanism for automatic locking of the differential.

Viscous Coupling Unit

History

The VC was invented in 1917 by an American Melvin Severn, but it didn’t find application back then. Only in 1964, the VC was firstly applied as a mechanism for automatic locking of the interaxle differential in the car Interceptor FF produced by the British company Jensen. Since the mid-60s VC units were widely used in the self-locking cross differentials installed on AWD passenger cars.

Design and operating

principle

The VC unit consists of numerous flat discs installed inside a sealed housing. The pack of discs includes a set of drive discs connected to the driving shaft and a set of driven discs connected to the driven shaft. Surfaces of discs have asperities and holes. The pack of discs is formed in such a way that driving and driven discs of the VC alternate and are located at a small distance from each other. The dilatant fluid, based on silicone (silicon-organic viscous substance), fills the internal space of the VC housing. This fluid has the property of thickening during rapid intermixing. In addition, the dilatant fluid has a large dilation coefficient when heated; it increases the viscous coupling’s efficiency, as the process of mixing puts additional pressure on VC discs which stick together (i.e. get pressed to each other by dilatating fluid) under the influence of heated up fluid.

Design of Viscous

Coupling

At

constant motion of the driving and driven shafts, the VC discs rotate at the

same speed and fluid particles do not intermix, having no impact on the disc

package. As soon as one of the shafts starts rotating faster than the other

one, discs of the VC package come into motion relative to each other. The

dilatant fluid, filling the VC housing, gets intensively mixed. The fluid

viscosity, thanks to its dilatant properties, starts to increase progressively.

Arising friction forces between fluid particles tend to level rotating speeds

of discs. If the speed difference is very high, the fluid becomes so viscous

that it acquires the properties of a solid substance – the VC gets blocked, and

the torque, transmitted from the drive shaft to the driven shaft via the VC

package plates, reaches its maximum value.

Viscous coupling

dismantling

Application of Viscous

Coupling

The viscous coupling is mainly applied in

all-wheel drive transmissions of passenger cars, where the VC is used either as

a limited slip differential (LSD), or plays the role of the locking clutch in

addition to the usual differential.

Operation scheme of

viscous coupling unit

When the VC is used to ensure differential

rotation of axles, it should be understood that the VC is by no means a

differential: it neither divides the torque, nor splits the power flows. In

design solutions of such transmissions, one axle is always rigidly connected to

the motor, while the other one is connected the differential via the VC. In

standard operation modes, the axle, connected via the VC, provides about 5-10%

of the contribution to the total tractive effort. In short-time slippage modes

of the main driving axle, the VC allows transmitting of up to 100% of efficiently

used power to the activated axle. The VC operation in the blocked mode usually

has a short duration, since its prolonged blocking leads to overheating and

drop of traction force of the activated axle down to zero. Despite this

drawback, the design solution with the activated axle is still used in SUVs (usually

the rear axle is activated).

Useful info about AWD

cars

When the VC is used for locking of the differential, it connects two components of the differential – either the differential housing (carrier) and one sun gear, or two sun gears ( both options are identical in their capacities). In case of simultaneous slippage of both components, the VC levels their angular speeds until the complete blocking of the differential. This design solution was used on interaxle differentials of Toyota Celica GT4 ST205, Subaru Impreza WRX GC8A and Alfa-Romeo 155Q4. The company BorgWarner is considered to be one of the leading producers of VC units.

Pros and cons of

viscous coupling

The list of the VC advantages includes the

following:

- improved flotation ability of the car and a

better capacity of making sharp turns;

- enhanced contact of tire when negotiating

sharp turns;

- VCs help to prevent wheel slipping and car

sideslips;

- better course-keeping ability of the car when

moving under severe weather conditions (slipper surface, rain, snow) thanks to

the torque transmission to the rear wheels, when the front wheels slip;

- tractive force may grow up to 100%;

- cars equipped with the VC can tow heavy

trailers.

When it comes to the VC drawbacks, it should be

noted that viscosity properties of the fluid filling the VC depend on the

intensity of its intermixing, and consequently on difference of angular speeds of rotating discs. But

there is no linear dependence of these properties, therefore it is impossible

to predict the braking ratio of the coupling discs. Because of this, self-locking

differentials with the VC have low efficiency. Differentials based on the VC

(without the use of the free gear differential) are not used in modern cars,

because of low efficiency of the VC and due to its cumbersome design. Since the

VC efficiency depends on the diameter of discs and the volume of the fluid

filling the VC housing, the installation of this mechanism increases dimensions

of the drive axle and leads to decrease of the vehicle’s clearance.

Problems and repair

The list of the VC failure symptoms includes: faulty behavior on the road, vibrations and squealing of tires when making a turn, wear of the rear tire. Commonly, VCs do not require any maintenance services during the useful life of the car. In many cases, repair specialists replace problematic VCs. But the high price of the VC forces drivers to look for any possible repair options.

To perform the VC fault check, it is necessary to lift up one of the wheels with the help of the leveling jack, shift to the N-gear and to spin the wheel manually. If the wheel rotates, then the VC is still “alive”. It is important to understand that the car wheel should not rotate quickly and freely (even with properly operating VC), but slowly with tension.

Video about VC issues in AWD Ford / Mountaineer 2002-2010

To fix the faulty VC specialists perform several procedures: VC flushing (can be performed with the help of different fluids – gasoline, silicone remover, etc.), replacement of friction discs, and change of dilatant fluid which is quite expensive.