Why ZF’s 8-speed Automatics are so Popular Among Major Carmakers?

Despite the fact that manual transmissions are simple, reliable, and easy to maintain, today it is clear that they are technically outdated, and the manuals are gradually being replaced by automatic transmissions. But it must be recognized that automatics are also not perfect in terms of reliability. However, there is a family of automatic transmissions, which surprises even ardent admirers of manual transmissions by its reliability. We are talking about the ZF8HP family designed and manufactured by the German company ZF Friedrichshafen.

The first version automatic transmission of this legendary family was developed in 2008 and was successfully tested on the BMW 7-series. Then this successful solution found application on other cars.

The 8HP

transmission family includes numerous modifications, and each of these

modifications has specific technical characteristics:

- 8HP45

- 8HP50

- 8HP55

- 8HP65

- 8HP70

- 8HP75

- 8HP90

- 8HP95

The ZF8HP

family includes 8-speed automatic transmissions designed for installation on

cars with a longitudinal engine positioning. When working on the 8HP family, ZF

engineers wanted to design more fuel-efficient transmission solutions in

comparison with its predecessor ZF6HP, and they managed to do it brilliantly.

The fuel consumption of cars equipped with ZF8HP transmissions was reduced on

average by 12-14% thanks to the use of 4 planetary gears instead of traditional

external gears. In addition, the German engineers managed to reduce the

gearshift time to 200 milliseconds and made it possible to shift gears in

non-sequential order. It can be said that ZF specialists managed to develop a

universal transmission solution, which is more efficient and lightweight than

its predecessor, but has the same dimensions as ZF6HP transmissions.

Design Peculiarities

In terms of

design, the ZF8HP family is an upgraded modification of ZF 6HP. Fuel efficiency

and dynamic qualities of these transmissions significantly exceeded those of

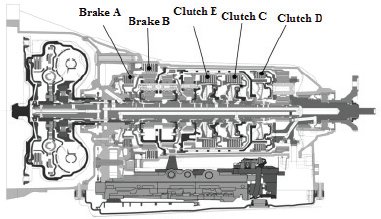

their predecessor. The structure of the ZF8HP transmission includes 3 clutch

packages and 2 brake drums. The planetary gear set (there are 2 of them) was

specifically designed for this transmission family. As a result, engineers

managed to achieve the maximum transmission of torque at low speeds. The gear

shifting is performed without losses of power, ensuring such a smooth gear

shifting that it can be easily compared to DCT or CVT transmissions.

Cross-section of the ZF 8-speed automatic transmission – 8HP45

Compared to ZF6HP transmissions, solenoids have also been updated; in the newer design they transmit torque quite smoothly and intensively starting from the 1-st gear. The operation of ZF8HP transmissions is performed by means of the mechatronics unit.

The fuel

consumption was also improved by the implementation of so-called “torque

converter disconnection”: when the car stops the torque converter gets disconnected

from the transmission by means of the clutch.

Why 8 speeds?

It was once believed that automatic transmissions needed no more than 3 or 4 gears. Nowadays, automatic transmissions have 8 or even 9-10 gears to ensure higher performance rates and to achieve better fuel economy, resulting in reduction of CO2 emissions.

If the transmission has many gears, the car engine operates with optimal RPM rates required for a particular situation, rather than operating with increased RPM rates when it is not necessary. It helps to reduce fuel consumption and unwanted emissions.

For this reason, ZF developed its legendary 8HP

transmission family to replace its equally popular 6HP transmissions. In 2014,

ZF engineers came up with a new modified 8-speed transmission version, which

allowed increasing the fuel efficiency even further.

Why ZF’s 8-speed automatics are still so popular?

Currently,

approximately 20 carmakers (including Audi, Chrysler, Jeep, Dodge, Jaguar,

Maserati, Alfa Romeo, Land Rover, Bentley, Aston Martin and even Rolls-Royce)

equip their cars with different 8HP modifications. What’s the secret of their

success?

The following cars are equipped with the 8HP automatics:

Maserati Ghibli

Rolls-Royce Phantom

The thing is that, unlike other transmission solutions, 8-speed transmissions from ZF can be installed on vehicles with different types of drives, including 4WD. This family of transmissions can be installed not only on gasoline-powered cars, but also can easily integrated into diesel vehicles as well as hybrid models. Moreover, ZF’s 8-speed automatics have a wide range of output powers.

The design

of these transmissions allows carmakers to position engines not transversally,

but longitudinally. These automatics are controlled by unique software, which

can be easily adjusted for a specific model.

Great video on the subject from Engineering Explained

It should also be borne in mind that the family

of ZF’s 8-speed automatics includes many modifications, which can be applied

for a wide range of different car models with different torque and power

qualities. Therefore, automakers can buy such a transmission from ZF, which

would be ideal for a particular car model, and then, adopt the software to

achieve required performance parameters. Thanks to such flexibility of 8-speed

automatic transmissions, ZF helps car makers to save significant financial

resources which would be needed to develop their own transmission solutions.

Repair and maintenance

Despite the fact that ZF’s 8-speed automatics are famous for their phenomenal reliability and outstanding technical characteristics, drivers should not forget about rules of automatic transmission operation and its maintenance.

It is not a secret that ZF8HP transmissions can

operate under heavy loads, but before aggressive driving it is necessary to

warm-up the transmission. These transmissions are very sensitive to

contaminated ATF, thus it is necessary to regularly check the transmission

fluid condition and change it, if necessary. The ATF change in 8HP

transmissions is performed together with the replacement of the pan and the

filter every 80,000 kilometers (or every 60,000 kilometers with aggressive

driving style).

In addition, it is necessary to test the torque converter for wear of friction plates of the torque converter lock-up every 100,000 kilometers, if the transmission operates under severe conditions.

All in all, it should come as no surprise that the 8HP automatic transmission family is still popular among leading carmakers and that these automatics compete in gear shifting quality with dual-clutch and CVT transmissions. No matter whether it is a big American truck (RAM) or a luxury car (Rolls-Royce Phantom), ZF’s 8-speed automatics will ensure smooth and rapid gear shifting.