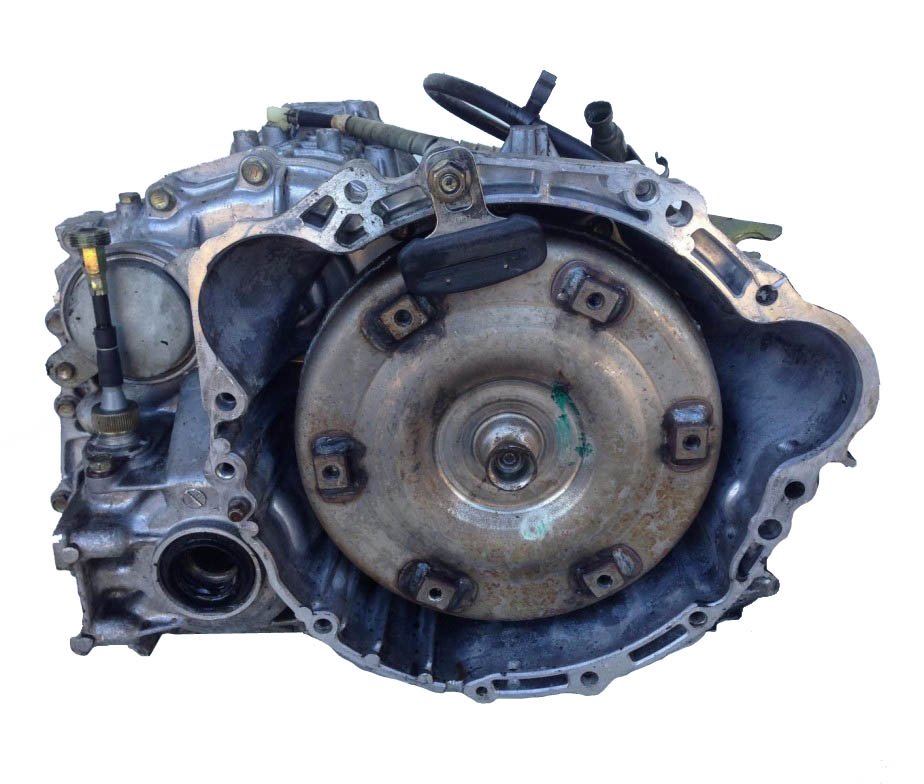

A240 Transmission parts, repair guidelines, problems, manuals

A241E, A242E, A243E

Transmission general data

| Number of gears | Transmission Type | Drive | Torque (Nm) | ATF (full capacity) L | ATF (change) L | ATF type |

|---|---|---|---|---|---|---|

| 4 | AT | FWD | 186 | 7,2 | 3,1 | Toyota Type T-IV |

This family of 4-speed automatic gearboxes 240 (А240 - 245, А246Е etc.) has been used since 1985 on famous and reliable Corolla as well as on Corona, RAV4 models with engine capacity up to 2 liters. The А246 unit without any significant updates is still used on Corolla and RAV4.This line of gearboxes also includes А140-series intended for higher torque. The A140E unit had been used since 1983 up to 2004 on more powerful Camry (with the engine capacity from 2 liters) assembled in the USA and Japan.

At the same time, a bit more sophisticated and highly-priced version named А540 was produced for even more powerful engines of Camry and Lexus. The modern line generation of this transmission family ( A245E/ A246E /247Е) hit the market in 2003. The А247Е model has a bit more improved hard parts aimed to endure higher torque from 2-liter engines. In 2003, the valve body was modified one more time: the unit received a linear solenoid of main pressure, the filter with a pan, as well as a significant improvement of the software part.

Despite the fact that this gearbox is not complicated and has a low price, the family of these 4-speed gearboxes is not so popular as more "sophisticated" Aisin analogs of "U" series. The market rivals of this gearbox are not German ZF4HP16 - 4HP18, competing with U240, but Jatco's 4-speed RE4F03 - RE4F04 units.

What are you looking for?

Overhaul Kit | Friction Kit | Friction | Steel Plate | Steel Kit | Band | Solenoid Kit | Solenoid EPC | Solenoid TCC | Pump | Shaft | Drum | Valve body | Torque converter | Hub | Piston | Piston Kit | Planetary Gear | Filter | Gasket | Bushing | Seal | Bearing | Pressure Plate | Stator | Differential | Retainer | Inhibitor Switch | Instruction manual | TOOLS & ACCESORIES | Sensor

Which cars run with this gearbox?

| Brand | Model | Year | Type | Engine |

|---|---|---|---|---|

| Daihatsu | APPLAUSE | 0 | 4 SP F/4WD | L4 1.6L |

| Pontiac | VIBE | 03-09 | 4 SP F/4WD | L4 1.8L |

| Pontiac | VIBE | 04-07 | 4 SP F/4WD | L4 1.8L |

Technical issues and repair guidelines

Overhauls in repair services commonly consist of repair of the torque converter, valve body, gearbox reassembly and replacement of spare parts and burnt friction components. Usually during the overhaul specialists have to deal with old gearboxes having the lockup mechanism worn to the glue layer, which reaches other frictions. Therefore, it is advisable to replace the whole set of friction discs during reassembly procedure. For problem-free exploitation of this gearbox, it is required to change fluid and (after 8-10 years) replace the filter on a timely basis. It is also recommended to replace the filter, if the gearbox has been used with burnt fluid or worn friction in the torque converter.

The most sensitive issue for the A240 unit is the wear-out of the lockup friction in the torque converter (TC) clutch which makes solenoids and valve body dirty.These gearboxes can cover substantial distances without any repair, but after 200 thousand kilometers it is advisable to monitor possible leakages of the pump seal and timely perform repair of the TC unit. Seals (of pump, axle shaft, cuffs etc.) start leaking because of a long exploitation period or due to wear-out of the TC lockup and resulting vibrations. The transmission shaft seal is replaced together with other seals. When delaying with replacement of seals, then it may be needed to change the rotating pump bushing.Solenoids are quite durable as well as, the brake band. The design of these elements hasn’t been changed since 1985.

Instruction manuals and useful links Suggest your link

| Link type | Source | Description |

|---|---|---|

| www.at-manuals.com | Scheme A140 | |

| www.at-manuals.com | Repair manual A140 | |

| www.at-manuals.com | Scheme A240 | |

| www.at-manuals.com | Repair manual A240 |