A4AF3 Steel Plate Transmission parts, repair guidelines, problems, manuals

Transmission general data

| Number of gears | Transmission Type | Drive | Torque (Nm) | ATF (full capacity) L | ATF (change) L | ATF type |

|---|---|---|---|---|---|---|

| 4 | AT | FWD | 190 | 6,3 | 4 | SP-III |

What are you looking for?

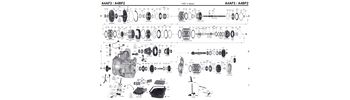

Overhaul Kit | Friction Kit | Friction | Steel Plate | Steel Kit | Band | Solenoid Kit | Solenoid EPC | Solenoid TCC | Pump | Shaft | Drum | Valve body | Torque converter | Hub | Piston | Piston Kit | Planetary Gear | Filter | Gasket | Bushing | Seal | Bearing | Pressure Plate | Stator | Differential | Retainer | Inhibitor Switch | Instruction manual | TOOLS & ACCESORIES | Sensor

Technical issues and repair guidelines

This transmission is considered to be very reliable, enduring long-time operation with contaminated transmission fluid. After a proper overhaul with spare parts reassembly specialists can give 1-2 years warranty. Many spare parts for A4AF3, A4BF3 transmissions are interchangeable with the whole A4AF family of automatic transmissions.The list of common spare parts includes the following: closed filter with felt, which is replaced in the process of each reassembly of the transmission that covered 150- 180 thousand kilometers; the brake band, which is replaced with the whole set of friction components when smelling the burnt ATF (Brake bands for engines up to 1.8 liters and over 1.8 liters are different), the brake band is replaced with the seal when operating for a long time with worn-out spare parts of the torque converter; in many cases specialists order the kit of bushings for the overhaul.

Seal boots are unified and can be applied for all relative automatic transmissions from КМ175 to F4A33, they are ordered during each rebuilding. If seals are replaced, but the torque converter is left untouched, then after a short time the seal will start leaking again and, as a result, it will be required to reassemble the oil pump. Friction elements in the Direct Clutch\ Forward packs burn 3 times more frequently. In most cases, all friction components are ordered for complete overhaul.

Another problem of the A4AF1 became a real “headache” for specialists in the process of the A4BF3 transmission repair: the drum gets burnt in each 5-th automatic transmission which comes to repair services, because of worn bushings and consequent oil leakage.Typical design problem of the Overdrive unit lies in damage of bearings caused by side loads from the differential.

Specialists often have to repalce the whole set of 6 solenoids and wiring. Even if the problem occurs in only one solenoid, technicians have to replace all of them because of short resource of other solenoids.Sometimes the problem of one of the linear pressure solenoids may lead to harsh shifting or forced actuation of the 3-rd gear without error codes. Problems usually lie in the fact that the solenoid valve wears out the channel because of contaminated ATF, starts hovering and at some moment gets wedged. Cleaning only contributes to the problem and the repair does not cover expenses. Generally this transmission is reliable like Hyundai cars when avoiding unnecessary overloads and overheating.

Instruction manuals and useful links Suggest your link

| Link type | Source | Description |

|---|---|---|

| Atra | A4BF2/A4AF3 Problems Before and After Rebuild | |

| automaticchoice.com | Scheme A4AF3 | |

| drive.google.com | Problems Before and After Rebuild A4AF3 |