CD4E Case Cover Transmission parts, repair guidelines, problems, manuals

Transmission general data

| Number of gears | Transmission Type | Drive | Torque (Nm) | ATF (full capacity) L | ATF (change) L | ATF type |

|---|---|---|---|---|---|---|

| 4 | AT | FWD | 250 | 9,5 | 3,7 | Mercon V |

What are you looking for?

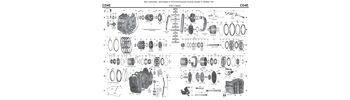

Overhaul Kit | Friction Kit | Friction | Steel Plate | Steel Kit | Band | Solenoid Kit | Solenoid EPC | Solenoid TCC | Pump | Shaft | Drum | Valve body | Torque converter | Hub | Piston | Piston Kit | Planetary Gear | Filter | Gasket | Bushing | Seal | Bearing | Pressure Plate | Stator | Differential | Retainer | Inhibitor Switch | Instruction manual | TOOLS & ACCESORIES | Sensor

Technical issues and repair guidelines

Experts assume that the design of the CD4E transmission is not good enough for 3 liter vehicles and profitable for repair services. This is due to the fact that CD4E is installed on long-living and unique vehicles, and also that this transmission is repairable and after some minor repair it operates for a long time. It is considered to be an American version of the 5HP19 transmission (on BMW-Audi-VW).Each overhaul of this transmission is accompanied by replacement of the filter. The filter has a felt membrane. ATF is changed every 60 thousand kilometers. The electrical part in the CD4E is considered to be simple and reliable. In some cases, transmission specialists only have to replace worn out block of solenoids.

One of the most vulnerable and repairable components in this transmission is a double drum, (clutch basket) Forward/Direct (6 Cylinder). Friction components and steel discs of both drums get replaced in the process of the drum repair. It is recommended to check the bushing of this drum together with steel and cover plates. This bushing is the 1-st element to get worn-out and requires replacement to prevent vibrations and losses of oil pressure.

Another common problem is the pump shaft failure caused by overloads. The oil pump often gets out of order when metal pieces appear in gears. The rubber of pistons rapidly wears out because of oil starvation and overheating. The kit of bushings is commonly ordered for repair of the CD4E transmission. Worn-out bushings in this automatic transmission is the sign of oil shortages and abnormal dynamic loads. In terms of design, the Forward planetary gear is considered to be another soft spot of the CD4E transmission. This planetary gear cannot endure ultimate loads from the engine. The reason is related to the bearing failure.

Torque converters of the CD4E are quite sensitive for such engines. One of the most frequent problems is the wheel hub bushing wear-out. The problem is related to insufficient oil pressure, overloads and overheating. The torque converter preventive repair should be performed in the course of the first overhaul after travelling 130-150 thousand kilometers. One more issue characteristic to the “old” CD4E transmissions is related to wear-out of the differential “teeth”. It is advisable to check the differential condition during the overhaul and reassembly.

Instruction manuals and useful links Suggest your link

| Link type | Source | Description |

|---|---|---|

| www.at-manuals.com | Scheme CD4E | |

| www | www.at-manuals.com | Solenoid identification CD4E, LA4A-EL |

| www | www.at-manuals.com | Application chart CD4E, LA4A-EL |

| drive.google.com | Repair manual CD4E ATSG |