Brake Band in Automatic Transmission: Purpose, Principle of Operation and Special Aspects of Its Adjustment

Automatic transmissions are

technically complex units, as they consist of numerous elements such as planetary

mechanism, torque converter, valve body, friction elements, brake band, etc.

Over time, these key car components become even more sophisticated, since car manufacturers

put in much effort to make their new models more reliable and comfortable. In

particular, they try to eliminate one of the most common transmission issues –

jerks during gear shifting. That’s where an automatic transmission brake band

comes into play. In this article, we will consider the main purpose of the

transmission brake band, its design peculiarities, place of installation, and

why it is necessary to adjust this element.

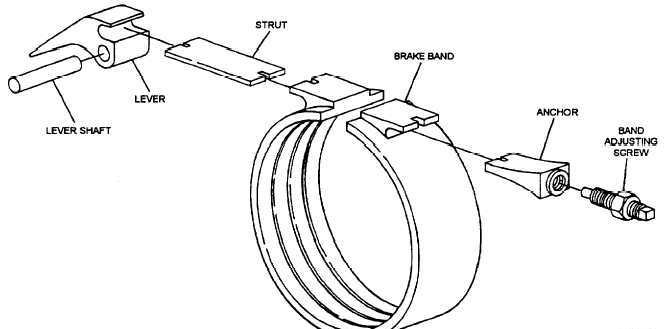

The brake band is included in the planetary gear control system together with friction discs, one-way clutch, etc. The automatic transmission brake band is necessary to block planetary gear elements for a short time. The composition of bands includes metal lined with organic friction material. This element locks the ring or sun gear or allows them spinning. Its operation is controlled by a hydraulic unit.

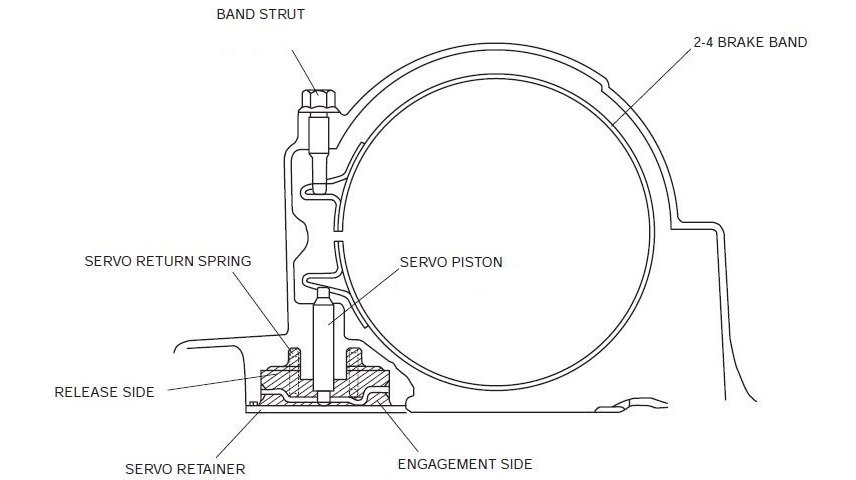

The band is installed on the gearbox casing: one end of the band is connected to the casing itself, while its 2-nd end is linked up with a running piston of the servo unit. Changing of the band state has a direct impact on the operation of the drum half of the clutch pack with the planet gear of the other half of the clutch pack. That’s how an automatics shift gears in compliance with the RPM rate.

The principle of the planetary mechanism holding/locking is similar to the principle of operation of the brake shoes. All automatic units are driven by ATF. When ATF reaches the servo mechanism, its piston starts moving under the pressure created by this fluid. As a result, the brake band tightens and locks elements of the planetary mechanism for a certain period of time. Once that time has elapsed, the planetary gear set gets unlocked and ATF shuts down the servo mechanism. As the fluid pressure equalizes, the band weakens, a special back-moving spring starts affecting the piston, and it returns to the initial position. The band returns to its free state.

Learn more about transmission brake bands and how they differ from clutches

A band

serves as a reaction mechanism, with the concept of operation similar to

multiple clutch discs and one-way clutches. But there is one key distinction. A

transmission band is strictly a stopping and holding component, while clutches

are intended for holding and running parts of the planetary gear set.

Peculiarities of design

Commonly, a brake band is made of a

flexible metal alloy (namely, numerous strips of this alloy). This material is durable

enough to withstand extreme abrasion and tear loads. To make the band more

durable and reliable, engineers apply a friction coating to the interior part

of the band.

Bands can be single or double

wrapped. Double wrapped bands are more efficient than their single wrapped

analogs. With time, bands wear out, leading to appearance of a gap between the

band and the drum. In result, a gearbox will start slipping.

Over time, metal strips and friction

coating of the band start wearing out, thus it is necessary to replace the band

at certain intervals. It is recommended to buy a new band complete with

adjusting screws (bolts). These screws can be installed both on the inside and outside

part of the gearbox depending on its design peculiarities. Both types of

positioning have their own advantages:

- In case of internal positioning, the screw head is not subjected to pollution and corrosion.

- External arrangement allows adjusting the band without dismantling of the housing. Moreover, such positioning of the bolts is more convenient and less costly, as the band adjustment in this case can be performed independently, without visiting a repair shop.

It is necessary to check and adjust the band tension not only after its replacement, but also after any transmission-related repair and maintenance services, including adding and changing of ATF. If the transmission starts kicking or jerking, the first point that you should check is the band state.

Most common issues related to the transmission band

The most common issues of the

planetary gear locking system (transmission brake band) and their consequences are

the following:

- Damage or wear of the friction layer on the brake band, resulting in incomplete locking of the planetary mechanism. As a result, during the process of gear shifting drivers can experience jolts or hear scratching noise in the automatic transmission;

- Breaking or other issues related to the piston cup of the servo mechanism. In this case, the brake band is also unable to block the planetary gear set. Each gear ratio change is accompanied by jerks in the automatic transmission;

- Damage of the piston rod in the servo mechanism. In case of mechanical damage, the piston get destroyed and its fragments/debris are transmitted to different transmission areas via ATF. If this problem is not addressed timely, then the transmission will get out of order;

- Wear or damage of the spring, contamination of the servo mechanism. In this case, the brake band will “wedge” moving parts of the transmission. As a result, the car won’t be able to start moving or R gear won’t work.

Band adjustment

To ensure normal operation of the

transmission brake band, it is necessary to regularly monitor the clearance

between the brake drum and the band. It is performed with the help of adjusting

screw (or hairpin with a lock nut).

Adjusting screw and hairpin with a lock nut

If the adjustment procedure is

performed by means of a hairpin, then it should be done with the help of a

torque wrench. It may be necessary to remove the transmission pan (if the

adjustment screw is located inside the gearbox housing).

Special instrument for a transmission brake band adjustment

It is interesting to point out that in some automatics brake bands are adjusted with the help of special rods of various lengths. In this case, the adjustment procedure is performed by dismantling of the unit and installation of the rod of the required length. Sets of rods are manufactured by manufacturers of such transmissions. It is desirable to perform some kind of preventative diagnostics by checking the band condition during ATF change. It is important not to stretch the band too much, as it can speed up the wear-out.

That’s how a transmission brake band is adjusted

It is also possible to adjust the

brake band without a torque wrench. In this case, the adjustment procedure is

performed as follows:

- The car should be stopped on a slope;

- To avoid uncontrolled movement of the car, it is necessary to put it on the hand brake, while putting a slop block (or a brick) under the wheel;

- Release the hand brake and check whether the slop block holds the car unmoved;

- Engage the hand brake again, while repositioning the slop block a few centimeters from the wheel;

- Loosen the lock nut to simplify the process of tightening the adjustment screw;

- Tighten the adjustment screw until a light stop;

- Release the hand brake, gradually loosening the adjustment screw of the brake band and wait until the car starts rolling;

- Tighten the adjustment screw by 2-3 turns (the number of turns is determined experimentally for a specific car until there won’t be any jolts during gear shifting).

Brake band adjustment in a legendary Ford T

Transmission brake band replacement

To install a new brake band, it is recommended to follow the instructions below:

- First of all, the car must be jacked;

- Remove the wheel to gain access to the transmission unit;

- Dismantle accumulator battery and air filter;

- Put the jack under the transmission unit and lift it up;

- Remove the transmission mount;

- Remove the bolts that hold the back cover;

- After removing the cover, it is possible to replace the brake band;

- Remove the old band and replace it with a new one;

- Close the back cover (do not forget to use the sealing compound), and reinstall all the dismantled components;

- Check the brake band state;

- Finally, check the car behavior on the road. Regardless of the acceleration rate, there should be no jolts during the process of gear shifting.

After removing the old band, it is

recommended to evaluate the nature of its wear. If the band gets out of order

after a short time, it is necessary to find the source of the issue.

Frequently, the problem lies in improper operation of the servo mechanism. As a

result, the planetary gear set wedges and wears the band.

GM TH700R4 4L60 automatic transmission brake band

It follows from the above that the brake band plays a significant role in ensuring smooth gear shifting in automatic transmissions. Thus, the owners of automatic cars should remember that the problem of jolts in transmissions can be frequently solved by adjustment of the band tension. Adjustment and replacement of the brake band can be performed independently by the driver. Regular checks of the transmission band tension helps to prevent jolts, loss of driving comfort, and excessive mechanical wear of the transmission unit.