Manual transmissions have long been an essential component of the automotive industry, providing drivers with a direct and engaging connection to their vehicles. Unlike automatic transmissions, which rely on complex hydraulic systems, manual transmissions require drivers to manually engage and disengage the gears, offering enhanced control and a more immersive driving experience. The act of shifting gears, feeling the mechanical connection, and being in full command of the powertrain contributes to the joy and art of driving.

In this article, we will delve into the world of manual transmissions and explore the various types available. From traditional non-synchronized transmissions to modern automated manual transmissions, each design offers unique characteristics and benefits.

Non-Synchronized Manual Transmissions

Non-synchronized transmissions, also known as "crash" transmissions, were the early iterations of manual transmissions. They lack a synchronizer mechanism, requiring drivers to rev-match and time their gear shifts accurately. These transmissions are more common in older vehicles and some specialty applications.

Driving a bus with non-synchronized gearbox

Sliding-Gear (Crash) Transmissions

Sliding-gear transmissions were the earliest form of non-synchronized transmissions. They employ a sliding collar mechanism that physically moves gears into place during shifting. While these transmissions offer simplicity and durability, they require skillful gear engagement and can produce gear grinding if not properly synchronized.

While sliding-gear (crash) transmissions are not commonly used in modern auto sports, they have played a significant role in the history of motorsports. In the early days of racing, before the advent of synchronized transmissions, sliding-gear transmissions were the norm.

Auto racing pioneers relied on sliding-gear transmissions for their simplicity, durability, and ability to handle the high torque demands of racing engines. These transmissions were commonly found in early race cars, including those participating in events like the Indianapolis 500 and early Formula racing.

Sliding-gear transmissions required skillful and precise shifting techniques from the drivers. In racing scenarios, where split-second decisions and quick gear changes can determine the outcome, drivers had to master the art of double-clutching and timing their shifts to minimize power loss and maximize acceleration.

Double-Clutch Transmissions

Double-clutch transmissions introduced a significant advancement in manual transmission technology. They utilize two separate clutches, one for odd gears and another for even gears. By preselecting the next gear while the current gear is engaged, double-clutch transmissions enable smoother and faster gear changes, minimizing the interruption in power delivery.

Synchronized Manual Transmissions

Synchronized transmissions revolutionized the driving experience by providing smoother gear shifts. They employ synchronizer mechanisms that match the speed of the engaging gears, allowing for seamless gear engagement without the need for precise rev-matching by the driver.

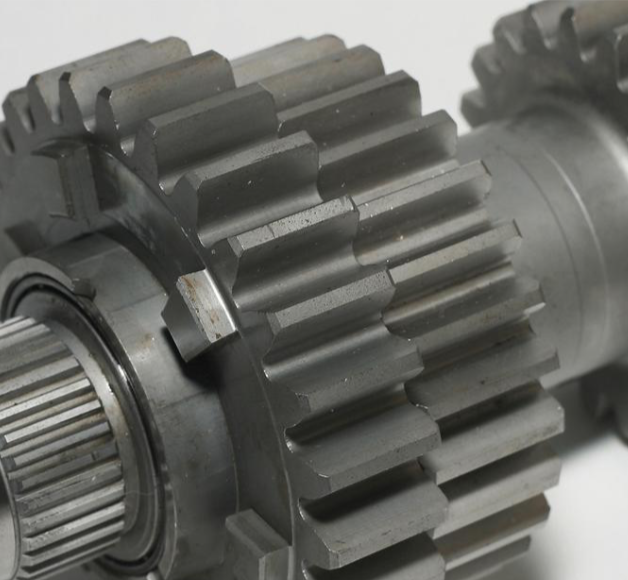

Constant-Mesh Transmissions

Constant-mesh transmissions are the most common type of synchronized transmissions in modern vehicles. They use a fixed set of gears that are always engaged with the output shaft. The synchronizer mechanism ensures smooth gear engagement by equalizing the speed of the engaging gears.

Synchromesh Transmissions

Synchromesh transmissions further refined gear shifting by employing cone-shaped synchronizers. These synchronizers provide a gradual engagement of the gear teeth, allowing for smoother and quieter gear changes. Synchromesh transmissions are known for their ease of use and widespread adoption in passenger cars.

Sequential Manual Transmissions

Sequential transmissions are a specialized type of manual transmission that operates differently from traditional manual gearboxes. Instead of the conventional "H-pattern" gear shifter, sequential transmissions utilize a sequential shifting mechanism. This means that the gears are arranged in a linear sequence, typically in a forward or backward direction.

In a sequential transmission, the driver shifts gears by moving the gear lever or paddle shifters in a sequential manner, usually forward to upshift and backward to downshift. Each movement of the lever or paddle results in a precise and sequential change to the next gear. Unlike traditional manual transmissions, there is no need to navigate through an H-pattern gate or use a clutch pedal.

Sequential transmissions are commonly used in high-performance vehicles, particularly in motorsports such as Formula 1, rally racing, and high-performance road cars. Their precise and rapid gear changes offer several advantages in racing scenarios, where split-second shifts can make a significant difference in performance.

One of the key advantages of sequential transmissions is their ability to shift gears quickly and seamlessly. The sequential shifting mechanism eliminates the need for the driver to coordinate clutch engagement, allowing for lightning-fast gear changes. This results in reduced shift times and improved acceleration, critical factors in motorsport competitions.

Automated Manual Transmissions

Automated Manual Transmissions (AMTs) combine the convenience of automatic transmissions with the control of manual transmissions. They are essentially manual transmissions with electronic controls that automate the clutch operation and gear changes.

Single-Clutch Automated Manual Transmission (AMT)

Single-clutch AMTs, also known as Single-Clutch Sequential Manual Transmissions, retain the traditional manual transmission layout but incorporate electronic control for clutch engagement and gear changes. These transmissions offer automated shifting, but the gear changes may still exhibit some delays or jerky motions.

Dual-Clutch Automated Manual Transmission (DCT)

Dual-clutch AMTs, also known as Dual-Clutch Transmissions (DCTs), provide lightning-fast gear changes by utilizing two separate clutches. One clutch handles the odd gears, while the other handles the even gears, allowing for seamless and rapid shifts with no interruption in power delivery. It's worth noting that although DCTs are classified as manual transmissions due to their clutch mechanism, they are predominantly used in automatic mode in modern vehicles. The advanced electronic control systems of DCTs enable automated shifting without the need for manual clutch operation, providing a smooth and effortless driving experience. DCTs are highly favoured in performance-oriented vehicles for their exceptional acceleration and precise gear changes, making them a popular choice among sports car enthusiasts. For example Bugatti installed DCT in their supercars.

Comparisons and Considerations

Each manual transmission type has its advantages and considerations. Non-synchronized transmissions offer simplicity and ruggedness but require skillful shifting. Synchronized transmissions provide smoother gear changes and are more user-friendly. Automated manual transmissions combine convenience and control but may have certain limitations. Continuously variable transmissions offer seamless power delivery but may not appeal to those seeking a traditional gear-shifting experience.

Performance and Efficiency Factors

Manual transmissions contribute to performance and efficiency in different ways. Non-synchronized and synchronized transmissions provide direct control over gear selection, allowing drivers to maximize engine performance. Automated manual transmissions offer convenience without compromising performance. Continuously variable transmissions optimize engine efficiency by continuously adjusting the gear ratio for optimal power delivery.

Driving Experience and Control Considerations

The driving experience and level of control vary among manual transmission types. Non-synchronized transmissions demand precise shifting skills, providing a raw and engaged driving experience. Synchronized transmissions offer smoother gear changes, making them suitable for everyday driving. Automated manual transmissions provide a balance between convenience and control. Continuously variable transmissions prioritize seamless power delivery and fuel efficiency.

Emerging Technologies and Future Trends

Advancements in manual transmission technologies are ongoing. Manufacturers are continually exploring ways to enhance performance, efficiency, and driver engagement. Advanced manual transmission technologies may incorporate improved synchronizer designs, refined automated systems, and innovative gear-shifting mechanisms.

Electrification and Hybridization of Manual Transmissions

As the automotive industry moves toward electrification and hybridization, manual transmissions are also being adapted to work in conjunction with electric powertrains. Hybrid manual transmissions may feature integrated electric motors, allowing for electric-only driving modes and improved overall efficiency.

Potential Impact on Future Manual Transmission Designs

The future of manual transmissions may witness further integration of advanced electronic controls, artificial intelligence, and connectivity features. These enhancements could enhance gear selection algorithms, optimize power delivery based on driving conditions, and provide personalized driving experiences.

Conclusion

Understanding the various manual transmission types empowers drivers to make informed decisions when purchasing a vehicle. By considering factors such as driving style, performance requirements, fuel efficiency, and personal preferences, drivers can choose a transmission type that aligns with their needs and enhances their overall driving experience.

Manual transmissions continue to play a crucial role in the automotive industry, providing drivers with an engaging and connected driving experience. While automatic transmissions have gained popularity, manual transmissions remain a favorite among driving enthusiasts who value the control, precision, and artistry of shifting gears.

In conclusion, exploring the different manual transmission designs allows us to appreciate the engineering ingenuity and advancements that have shaped the driving experience. Whether it's the simplicity of non-synchronized transmissions, the smoothness of synchronized transmissions, the convenience of automated manual transmissions, or the efficiency of continuously variable transmissions, manual transmissions continue to evolve and adapt to meet the needs of modern drivers. By understanding these designs, we can make informed choices and truly enjoy the art of driving.