Peculiarities of Fluid Change in CVT Transmissions

Nowadays, many modern cars (passenger cars as

well as SUVs) more and more often are equipped with a CVT transmission instead

of a conventional automatic transmission. This is related to the fact that this

type of transmission provides improved dynamic characteristics, better fuel

economy, and this transmission is considered to be more convenient. Transmission

fluid in CVT transmissions plays no less important role than in conventional

automatic transmissions. Thus, well-timed changing of transmission fluid in the

CVT unit is considered to be a key maintenance procedure.

In this article, we will consider the main peculiarities of fluid change procedure in CVTs, its time intervals, how to do it accurately, and what facts should be taken into account when choosing a fluid variant for your CVT transmission, as these questions often bother owners of Nissan, Renault, Mitsubishi, Subaru, Toyota models equipped with CVTs.

CVT fluid change: when

and why it should be done

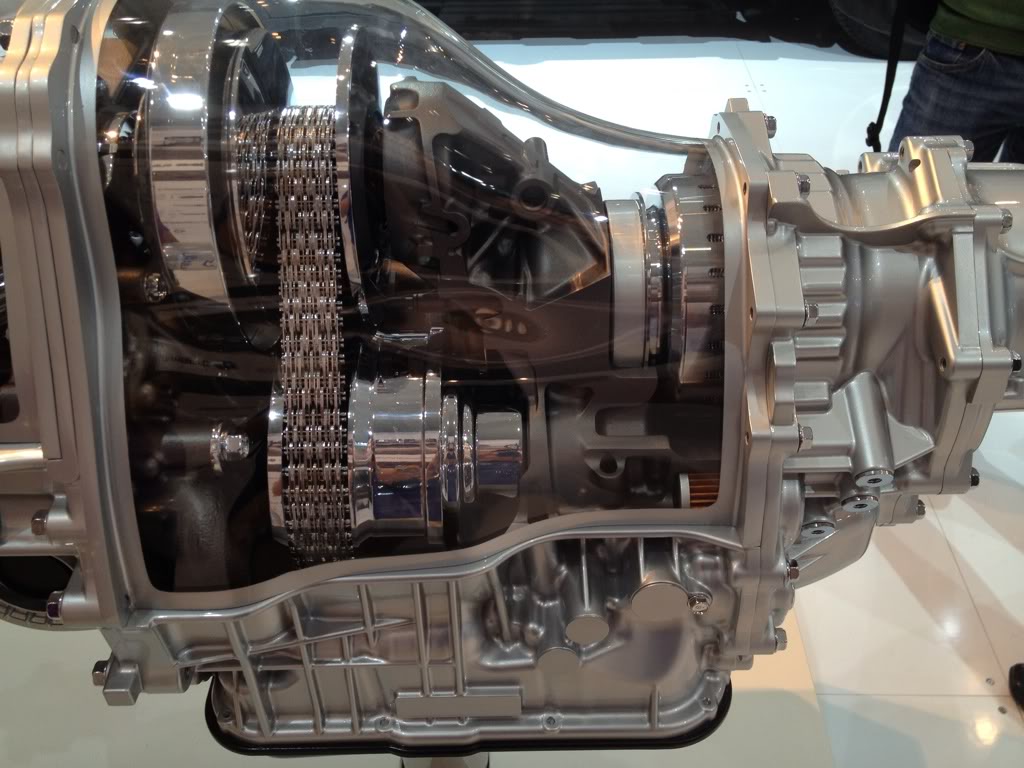

The fluid change procedure for CVTs is quite similar to the same maintenance service for automatics. However, it must be remembered that there are some procedure peculiarities and allowances specific only to CVT fluids. It must be emphasized that CVTs significantly differ from automatic and robotic transmissions in terms of design and principles of operation. This type of transmission is extremely sensitive to high loads and fluid quality. In fact, it means that CVTs are not intended for aggressive driving and harsh operating conditions.

As for CVT transmission fluid, with time it loses its properties, becomes contaminated with wear products, etc. In other words, even if the manufacturer claims that the transmission is maintenance-free, in reality, it is not entirely true.

As practice shows, experienced transmission repair specialists recommend changing fluid and filter in CVTs, automatic and robotic transmissions every 40-50 thousand kilometers. All these types of transmissions have one common component – a valve body. This complex and quite expensive unit is one of the most frequently repaired elements in automatically-actuated transmissions. It is the first component to get out of order because of contaminated oil. In case of operating under severe conditions, a fluid change interval is reduced to 30-35 thousand kilometers. Severe conditions include the following :

- Towing;

- Dynamic accelerations and slowdowns;

- Long-time non-operation (idle) state in hot weather. When driving in traffic jams, there is no airflow to the CVT housing and cooling radiator, therefore the risk of overheating is significantly increased;

- Off-the-road driving. Slippages of driving wheels can be quite harmful for CVT transmissions.

It is also worth noting that the deterioration of operation properties and contamination have a destructive effect on other parts of the CVT unit (belt, pulleys, cones, etc.) Given that it is difficult and quite expensive to fix a CVT, transmission fluid change should be taken very seriously.

How to check CVT fluid

status

- Drop test. Put a small amount of CVT fluid on a clean white napkin. Fluid opacity indicates a large amount of suspension of wear products from friction clutch packs, which negatively affects the oil channels and operability of the solenoids. The smell of burning indicates repeated overheating of the operating fluid, which usually occurs due to some issues with the CVT cooling system or pressure drops in the lubrication system. As a result, friction discs start slipping because of pressure drops, thereby causing fluid overheating. Depending on the year of manufacture and the transmission unit model, the CVT can be filled with a blue, green or red fluid. For a clear analysis of a drop specimen, it is desirable to have a sample of a new CVT fluid.

- Fluid degradation counter (or simply fluid counter). The electronic control unit of many CVTs has a mathematical algorithm for calculating the residual service life of the working fluid. The calculation takes into account the total operating time of the CVT unit, fluid temperature and operating loads. The fluid counter calculates the oil degradation level in arbitrary measurement units. . The number of points calculated by the oil counter depends not only on the time of fluid operation, but also on a number of other factors, the main one is the temperature of operation. These points must be especially familiar to many owners of Toyota and Nissan vehicles. For instance, Toyota recommends changing the fluid when the counter reaches 210,000 points

To monitor the CVT fluid condition and fluid counter level in particular drivers can use CVTz50 software

However, two methods mentioned above do not always give you a 100% guarantee that the fluid will be changed timely. Therefore, transmission repair specialists recommend taking into account two rules:

- Change fluid after purchasing a used car. Even if the previous owner will assure you that he changed the fluid before selling the car, it is better to be safe than sorry as CVT repair costs are usually quite high.

- Adhere to recommended fluid change intervals specified in the car manual. But it is possible that you’ll have go against the manufacturer’s recommendation, as aggressive driving and severe operating conditions can bring the fluid change time much closer.

Fluid change in CVT

transmissions

For CVT transmissions it is recommended to use

only the original fluid under the brand name of the manufacturer. Usage of the

third-party fluid is possible only if the product meets allowable tolerances of

the original fluid. Operating characteristics of transmission fluids have been

changing together with the development of CVT technologies. For example, CVTs

installed in Nissan cars can be filled with fluids of NS-1, NS-2 or NS-3

classes. Before the fluid change procedure, it is necessary to examine the

manual, where you’ll find some info on the filling volume and type of fluid.

When it comes to the fluid change, evidently there are two possible ways of action:

- Visit a professional repair shop

- Perform the procedure independently

When we are talking about possible fluid change methods, there are also two possible options: partial (incomplete) or complete fluid change.

- Partial fluid change in CVTs implies so-called fluid refreshment. To put it simply, part of the lubricant is drained, and then it will be necessary to fill in exactly the same amount of fluid as has been drained and adjust the fluid level in the CVT unit.

To perform this procedure, firstly it is necessary to warm up the transmission unit by driving 10-15 km. Then you need to lift the car on a lifter and drain some part of used fluid. Then, exactly the same amount of fluid (the same manufacturer, properties, tolerances) must be filled into the transmission unit. This approach will help to avoid possible negative consequences of combining different types of fluid. It is important that with the use of this method you can refresh only 1/3 or a little more of the total CVT fluid amount. To achieve 100% refreshment of the fluid, this procedure must be repeated at least 3-4 times (with the interval of 500-700 km). It is also recommended to perform a double replacement of all automatic transmission filters.

- Complete fluid change in CVTs is performed using a special device. The whole procedure implies a displacement method, when a new fluid actually squeezes out the old fluid out of the transmission unit.

The device is connected to nozzles of the CVT cooling system, and then the fresh fluid is supplied under pressure, squeezing out the used fluid. The device has inspection windows so that the technician can control the fluid pumping process, determining the degree of fluid condition by the fluid color. The main advantage of this method is the complete fluid renewal in the CVT unit. The special equipment also allows performing a flushing procedure before pumping fluid into the transmission unit.

DIY fluid change

If owners of CVT-equipped cars want to perform

the fluid change procedure by themselves and do not have access to a special

equipment, they should do the following:

- Unscrew the plug and drain the old fluid;

- Remove the transmission pan to remove any wear debris;

- Replace the oil filter (if necessary it is also possible to replace the coarse mesh filter);

- After cleaning joint surfaces, it is necessary to install a new gasket and attach the pan. Screw in the drain plug;

- Fill in the new CVT fluid via the funnel inserted into the dipstick port. If the fluid level before the procedure was normal, the filling volume should correspond to the amount of old fluid;

- Check the fluid level using the instructions specified in the manual;

- Reset the fluid degradation counter. It can be performed with the help of many universal diagnostic devices. As practice shows, after changing fluid without resetting the fluid counter, the CVT unit starts operating with jerks and kicks. At the same time, CVT transmission repair specialists say about a peculiar trend: CVT belts and cones frequently get damaged after changing the fluid without resetting the fluid counter.

It is often claimed that a CVT-equipped car is

more comfortable than automatic transmissions and a more reliable solution

compared to DSG-type solutions. However, it is important to understand that CVT

units are not intended for operation under severe conditions. In practice, it

means that such a unit needs regular and quality service. At the same time,

fluid change and filter replacement in CVTs are considered to be key procedures

that transmission repair experts recommend performing every 40-50 thousand

kilometers.