Tips to Select the Right Engine + Transmission Combination for a Truck

A fleet truck can be easily overloaded if it

does not come with the proper powertrain (engine+ transmission) combination,

thereby resulting in increased expenditures for maintenance servicing. The combination

of these components plays a critical role for the truck performance capacity.

There is no standard solution when it comes to choosing the perfect powertrain

for any truck. In this article, we will consider some helpful tips for owners

of truck fleets on selecting truck components that have a significant impact on

its performance, fuel economy and maintainability.

Application target

The first question that has to be clarified

during the quest for a perfect powertrain system is the future application of

the truck. When talking about the truck application, it is necessary to

consider such factors as truck’s operating weight, max possible starting grade,

and designated road surface help to specify what transmissions and engines will

make your truck a real asset for any business. It should be noted that there

are some transmissions that have certain restriction concerning the GCVW rates.

All these important parameters mentioned above help to determine what kind of

gearing and torque will be needed to operate most efficiently at specific

cruise speeds.

Significance of Drivability

One of the most important aspects for truck

drivers is the drivability of the vehicle. Depending on the application, it is

necessary to take into account a wide range of parameters (smoothness of

operation, maneuverability, speed of gear shifting, availability of creep mode)

that ensure safe and efficient operation of the truck.

For instance, it is extremely important for ambulance/fire

and emergency vehicles to shift gears and pick-up the speed as fast as

possible. In applications that are frequently exposed to stop-and-start

traffic, it is necessary to pay attention to such aspects as clutch wear and driver

fatigue (in such cases automatics may be more preferable).

Engine Displacement

The requirements imposed on the engine

displacement greatly depend on the vocation of a specific truck. For example,

trucks used for transportation of heavy loads may benefit from using a smaller

engine displacement in order to save weight. Fleet managers should collaborate

closely with dealers to determine the required engine size and to come up with

the most efficient powertrain combination.

Manual vs Automatic

Selecting an ideal transmission type is crucial when considering a particular kind of fleet operation. When it comes to choosing between manual and automatic gear shifting units for trucks, it is necessary to keep in mind the following aspects: vehicle application, driver’s expertise, main characteristics of the engine (power, torque).

Truck drivers with different professional

competence levels have recently been giving preference to automatics because of

numerous advantages of modern self-shifting solutions. Automatics free drivers

from the necessity to constantly engage the clutch pedal and shift gears

manually, thereby allowing them to concentrate on the road and reduce the

possibility of road accidents.

As the global automotive industry gradually

shifts to complete automation regarding transmission solutions, owners of truck

fleets also cannot ignore the fact that new heavy-duty automatic gearboxes

outperform conventional manuals in several important aspects (from performance

capacity to maintenance cost).

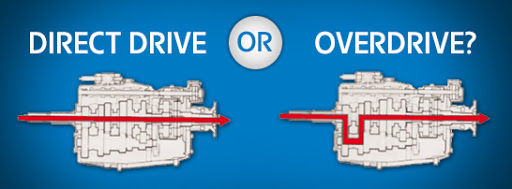

Direct-Drive or Overdrive

Once the transmission type has been specified,

fleet owners have to decide on a direct-drive or overdrive configuration. Until

recently, overdrive options have been enjoying much more popularity. The thing

is that previously the automotive market offered a limited number of direct-drive

manuals on the market, and there was restricted axle ratio coverage to work

with the direct-drive. But most of modern AMTs come in both direct and overdrive

configurations. In fact, direct-drive units are more fuel efficient than their

overdrive analogs.

Performance and Economy

Another important factor to consider when

determining the main powertrain components is the priority between the

performance and economy of the fleet truck. If good performance characteristics

allow drivers to feel more comfortable on the road, high economy rates allow

businesses to reduce the overall cost of operations. Achieving the right

balance between these two important parameters is a big factor when determining

the right powertrain setup.

Drivers

Driver satisfaction also should not be

disregarded in this important design aspect. The right powertrain is not just

about the performance and economy ratio. The correct combination should allow

the driver to operate the truck in the most comfortable way possible, thereby

avoiding excessive fatigue and increasing safety on the road.

The competence and flexibility of drivers can

differ, depending on the kind of fleet and peculiarities of the business. In

fact, most of the drivers now are reluctant to drive manual trucks or simply

don’t know how to do it. When considering the powertrain configuration, it is

important for fleet owners to understand the level of driving skills of their

employees.

Learn what it is like to drive a truck equipped with an AMT transmission and how’s it different from manual truck experience

Resale Value

Finding the appropriate powertrain setup also

should be examined from the resale perspective. It is not a secret that major

vehicle manufacturers gradually shift from manual to automatic transmissions,

and it has a significant impact on the used vehicles market. Currently,

automatic trucks have a higher resale value.

When it comes to the engine, the choice between

diesel and gasoline-powered engines depends on qualities for a specific

business. While diesels ensure longer operation and better fuel economy, while gasoline

engine vehicles are notable for a lower upfront cost.

Summary

All in all, a proper selection of the main powertrain components, namely engine and transmission, cannot be performed separately, as both components are interdependent when it comes to ensuring the highest performance and economy rates. Moreover, it should be born in mind that operating characteristics must match application peculiarities of the truck.