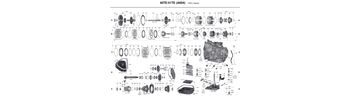

42RLE Transmission parts, repair guidelines, problems, manuals

Transmission general data

| Number of gears | Transmission Type | Drive | ATF (full capacity) L | ATF (change) L | ATF type |

|---|---|---|---|---|---|

| 4 | AT | RWD | 11 | 4 | Mopar ATF+4 |

The 4-speed automatic transmission 42RLE was designed jointly with 42LE (front-drive) and was produced since 2003, installed on the powerful RWD Chrysler of the 300-series, Liberty Jeeps, Cherokee (V6 and V8) and Dodge pickups with engines from 2.7 l up to 4 liters.

The 4-speed automatic transmission 42RLE was designed jointly with 42LE (front-drive) and was produced since 2003, installed on the powerful RWD Chrysler of the 300-series, Liberty Jeeps, Cherokee (V6 and V8) and Dodge pickups with engines from 2.7 l up to 4 liters.

In terms of design, the 42RLE is a simplified rear-driven version of the FWD A606 (42LE), which doesn’t have the differential, chain and some other elements for the front drive.

What are you looking for?

Overhaul Kit | Friction Kit | Friction | Steel Plate | Steel Kit | Band | Solenoid Kit | Solenoid EPC | Solenoid TCC | Pump | Shaft | Drum | Valve body | Torque converter | Hub | Piston | Piston Kit | Planetary Gear | Filter | Gasket | Bushing | Seal | Bearing | Pressure Plate | Stator | Differential | Retainer | Inhibitor Switch | Instruction manual | TOOLS & ACCESORIES | Sensor

Which cars run with this gearbox?

| Brand | Model | Year | Type | Engine |

|---|---|---|---|---|

| Chrysler | 300 SERIES | 04-10 | 4 SP RWD | V6 2.7L 3.5L |

| Dodge | CHALLENGER | 08-11 | 4 SP RWD | V6 3.5L |

| Dodge | CHALLENGER | 08-14 | 4 SP RWD | V6 3.5L |

| Dodge | CHARGER | 05-10 | 4 SP RWD | V6 2.7L 3.5L |

| Dodge | DURANGO | 04-08 | 4 SP R/4WD | V6 3.7L |

| Dodge | MAGNUM | 04-08 | 4 SP RWD | V6 2.7L |

| Dodge | NITRO | 07-11 | 4 SP R/4WD | V6 3.7L |

| Dodge | PICKUP/DAKOTA | 03-11 | 4 SP R/4WD | V6 3.7L |

| Dodge | PICKUP/RAM 1500 | 06-16 | 4 SP RWD | V6 3.7L |

| JEEP | CHEROKEE | 03-14 | 4 SP 4WD | V6 3.7L |

| JEEP | CHEROKEE | 00-13 | 4 SP R/4WD | L4 2.4L 2.5L L6 3.6L 3.7L 4.0L |

| JEEP | LIBERTY | 03-12 | 4 SP R/4WD | L4 2.4L V6 3.7L |

| JEEP | WRANGLER | 06-16 | 4 SP R/4WD | V6 3.8L |

| JEEP | WRANGLER UNLIMITED | 06-16 | 4 SP R/4WD | L4 2.8L V6 3.8L |

| Mitsubishi | ENDEAVOR | 03-10 | 4 SP R/4WD | V6 3.8L |

| Mitsubishi | RAIDER | 06-08 | 4 SP R/4WD | V6 3.7L |

Technical issues and repair guidelines

The common repair kit for this transmission includes the following:

- repair kit of gaskets and seals.

- kit of friction components.

- kit of steel discs (less frequently)

This article covers the common issues with the Jeep Wrangler 42RLE Automatic Transmission, as well as some possible solutions. - Some of the more common problems include failed gear shifts, clutches and faulty torque converters, as well as sporadic torque converter clutch overdrive engagement problems. These issues can often indicate transmission problems which may require a rebuilt transmission. In some cases, a brand new transmission may be necessary. Older Jeep vehicles are especially prone to failure problems due to their age, and any indications of severe transmission problem should be addressed immediately. Symptoms such as loss of speed or torque converter speed can indicate a valve body issue which is a widespread issue in newer Jeep Wrangler vehicles.

This is when the transmission slips and may even cause your car to lose transmission fluid. This could be due to a faulty connection or the torque converter, which is what causes the transmission engine to slip. A slipping transmission can cause fault codes to appear on your vehicle's diagnostic scanner and indicate that you need repair. To fix this issue in a Jeep Wrangler, you will need to give your transmission a full flush and replace the valve body with a new one. This should stop your vehicle from slipping as it did before.

Causes of most transmission problems in a Jeep Wrangler can be traced to low fluid levels, leaks and lack of proper maintenance. Checking the fluid level in the transmission is one of the most common Jeep Wrangler problems. If the fluid level is too low, it can cause your car to slip or jerk as you shift gears. To avoid this problem, make sure to check your car's transmission fluid level regularly and top it off when needed. It is also important to get your car serviced regularly and use the right tools and experience to lessen transmission fluid loss due to leakages. Cars are unlike motors, so regular oil changes may not solve their problems; instead, you need to check their transmission fluids.

Automatic transmissions can be tricky and can cause a variety of problems. 42RLE Automatic Transmission Problems and Repair Solutions involve understanding the system, diagnosing the issue, and finding the right repair shop to fix it. Common problems include a transmission that tends to shift too hard or grinds when shifting. Many Dodge Ram owners experience problems in second gear where they enter a limp home mode and can only go up to 40 mph. To fix this, you may need to go to a repair shop and have your transmission flushed or replaced.

The 42Rle Automatic Transmission is found in some Chrysler vehicles and has been known to cause problems with shifting, dropping vehicle speed, and poor fuel economy. To operate the torque converter clutch, the transmission must first lock it in place. Once it is locked, the transmission will then disengage the clutch to help improve fuel economy when accelerating at certain speeds. If this does not work, you may need to unlock the torque converter clutch manually. The manual pdf that describes how to do this can be found online.

The torque converter lock-up wear-out usually results in vibrations and wear of the pump bushing (which is the same in A604-A606 and is included in the kit of bushings). The problem with the pump bushing manifests itself in leakages through the pump seal. If this problem stays neglected, then it may lead to the oil pump replacement.

The block of solenoids in the 42RLE is a common reason for many issues in this family of automatic transmissions. The resource of this block is not a large one, and the ТСМ unit loads solenoids quite intensively forcing the torque converter locking at the first opportunity to increase acceleration characteristics of the car.

The Clutch Hub (2-4 Clutch) is a typical vulnerability of these transmissions. In terms of design, this automatic gearbox has problems with the hub and a sun gear. The problem is also provoked by shortages of the oil pressure.Sensor Output Speed (VSS) and Input (TSS) cannot endure high temperatures and oil contamination by the metal dust. Pump bushings, gaskets, pistons, planetary gears get out-of-service because of insufficient oil pressure. These typical problems also occur in the family А604-А606.

This reliable transmission may serve for a long time. But it should be kept in mind that engineers of Chrysler wanted to win the competition with other fast automatic transmissions, therefore they adjusted TCM settings in such a way that the accelerator pedal easily forces the transmission work 101% of its capabilities without leaving any reserves.

Instruction manuals and useful links Suggest your link

| Link type | Source | Description |

|---|---|---|

| ATRA | 42RLE ATRA Technical Bulletin | |

| www | wikipedia | Wikipedia article about 42RLE |

| www | Sonnax | 42LE, 42RLE Variable Line Pressure |

| drive.google.com | Instruction 42RLE |