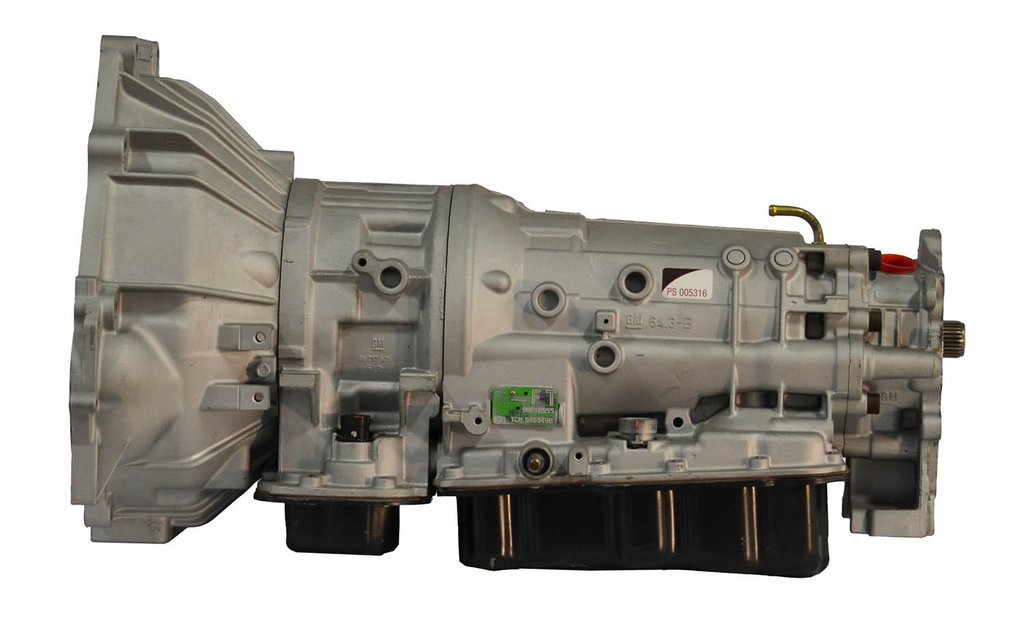

4L30E Transmission parts, repair guidelines, problems, manuals

AR25, AR35

Transmission general data

| Number of gears | Transmission Type | Drive | Torque (Nm) | ATF (full capacity) L | ATF (change) L | ATF type |

|---|---|---|---|---|---|---|

| 4 | AT | RWD/AWD | 350 | 9,7 | 4,6 | Dexron VI |

The 4-speed automatic transmission 4L30E is the successor of a reliable 3-speed transmission 3L30E, which has been used since 1969. These transmissions were made in the USA and in Europe (Strasbourg) under the name AR25 for RWD Opel Omega and AR35 for a 3-liter Katera.

The 4L30E has been installed since 1990 on RWD and AWD BMWs of all series with engine capacity of up to 3 liters, but it was more widely used on GM, Opel Omega, Isuzu and even on Honda Passport where it proved to be highly efficient.

What are you looking for?

Overhaul Kit | Friction Kit | Friction | Steel Plate | Steel Kit | Band | Solenoid Kit | Solenoid EPC | Solenoid TCC | Pump | Shaft | Drum | Valve body | Torque converter | Hub | Piston | Piston Kit | Planetary Gear | Filter | Gasket | Bushing | Seal | Bearing | Pressure Plate | Stator | Differential | Retainer | Inhibitor Switch | Instruction manual | TOOLS & ACCESORIES | Sensor

Which cars run with this gearbox?

| Brand | Model | Year | Type | Engine |

|---|---|---|---|---|

| Acura | SLX | 96-99 | 4 SP RWD | V6 3.2L 3.5L |

| BMW | 3-SERIES | 92-00 | 4 SP RWD | L4 1.8 1.9L L6 2.5L 2.8L |

| BMW | 5-SERIES | 90-99 | 4 SP RWD | L6 2.5L 2.8L |

| BMW | 7-SERIES | 00-01 | 4 SP RWD | L6 2.9L |

| Cadillac | CATERA | 98-01 | 4 SP RWD | V6 3.0L |

| Honda | PASSPORT | 94-02 | 4 SP RWD | L4 2.6L V6 3.2L |

| Isuzu | AMIGO | 99-02 | 4 SP RWD | L4 2.2L V6 3.2L |

| Isuzu | AXIOM | 02-04 | 4 SP RWD | V6 3.5L |

| Isuzu | RODEO | 91-04 | 4 SP R/4WD | ALL |

| Isuzu | TROOPER | 90-02 | 4 SP 4WD | V6 3.2L 3.5L |

| Isuzu | VEHICROSS | 99-01 | 4 SP 4WD | V6 3.2L |

| Opel / Vauxhall | CATERA | 00-01 | 4 SP RWD | V6 3.0L |

| Opel / Vauxhall | FRONTERA | 00-04 | 4 SP RWD | L4 2.2L V6 3.2L |

| Opel / Vauxhall | OMEGA | 00-03 | 4 SP RWD | L4 2.0L 2.2L 2.5L V6 2.5L 2.6L 3.0L 3.2L |

-

-

- Accumulators, Accumulator Piston, Acummalator Kit, Accumulator Piston Kit

- Adapter, Adapters, Grommet Valvebody

- Bands, Brake band, Lining

- Bearings, brg, Mainbearing

- Bellhousings

- Cover Bolt, Cover Bolts, Mounting Bolt, Mounting Bolts, Pan Bolt, Pan Bolts, stud, studs, Split Pin

- Booster, Boosters, Boost Regulator, Boost Spring, Boost Valve, Lockup Boost, Booster kit, Kit Boost, Kit Boost Valve

- Bushings, Bush,

- Casing, casings, cases

- Case Covers, Cover, Dust Cover,

- Connectors, loom

- Drums, Contender Drum, Drum with Bearing, Reverse Drum, Drum Part

- Electrics, Electric, Electronic, Electronic Shift, Electronics, Pin Wiring, Relay Control Switch, Neutral Relay, Main Relay

- Extn Hsg, Extn.Hsg, Extensions, Extension, Overdrive Housing, TAIL HOUSING, TAIL EXTENSION

- Filters, Filter Cartridges, Filter Cartridge, Oil Pan Filter, Inlet, Filter Kit

- Friction Discs, Frictions, fric, Friction Disc, Friction, Friction Plate, Friction Ring, fric., Clutch Plate, Friction Lining

- Friction kits, friction pack, friction set, High Energy Clutch Friction Module, Friction clutch

- Shields, Shield

- Gaskets, gsk, gskt, , Cover Gasket, Cover Gaskets, Case Gasket, Case Gaskets, Filter Gasket,Filter Gaskets

- Gasket Pan, Pan Gaskets, Pan gasket, Filter Gasket,Filter Gaskets

- loom, Harnesses, Line Connector, Wiring, Cover Wiring, Cable, Signal Cable, Cable, Power Cord

- Housings

- Hubs, Hub Insert

- Inhibitor switches, Inhib.Swtch, Range Selector Switch, Selector, Range Switch, Position Switch, Gear Selector, ISM

- manuals, Technical manual, Repair manual, service manual, Manual, VIDEO & AUDIO, tapes

- Lever, Levers, Lever Control Rod, Knob, Lever Pin, Lever Collar, SHIFT LINKAGE, Linkage Rod, Linkage, Park Pawl, Rod

- o-ring, o ring, 0ring, 0-ring, 0 ring, ORing, Ring, O-Rings, o-ring, O'Ring

- O/D,

- ohk, OHK kit, Overhauls, mok, Overhaul kit, Masterkit, Master kit, Master Overhaul, Repair package, Overhaul, Rebuild kit, Master Rebuild, Super Rebuild Bundle, Banner Kit, SUPER KIT, SUPERIOR KIT

- Pans, Crankcase, Oil Pan

- Piston Pins, Servo Pin, Piston Pin, Band Pin, Retaining Pin, Retaining Pins

- Pistons, Apply Piston, Pack Piston, High Piston, Damper Piston, Piston Damper, Piston Plate, Interm. Servo Pist, Piston Seals, Piston Seal Ring, Piston Seal Rings, Piston Seal, Piston Cover, Piston Covers, Rear Servo, servo piston, Piston Retainer, Piston Retainers, Servo kit, Super Servo, servo, Shift Pison

- Pressure Plates, Apply Plate, Backing Plate, Backing Plates, Backplate, Ret Plate, Dish Plate, Press Plate

- Pumps, Rotor, Vane, Vanes, Kit Pump Vane/Ring

- Regulators, Main Pressure Regulator, Main Pressure Reg, Pressure Regulator, Forward Regulator, Secondary Regulator, Pressure Reg, Press Reg

- Regulator Valves

- Seals, Metal clad seal, Lip Seals, Connector Hole Seal, Lip Seal, Main Seal, Radial Lip Seal, Main Seal, Manual Seal, Oil Feed Seal, Side Cover Seal, Seal Cooler, Seal Oil Cooler, Case Seal

- Pump seal

- Seal Rings, Seal Ring, Sealing Rings, Piston Seal, S/Ring, SEALING RINGS S/Ring, Accumalator Seals

- Reprogramming Kit, Kit Reprogram, Reprogram Competition, Kit Shift, Kit Auto Shift, Kit Stick Shift, Shift Correction Kit

- Sleeves, SLEEE, Ground Sleeve, Overlap Control Sleeve, Seal Ring Sleeve, Repair Sleeve, Regulator Sleeve, Modulator Sleeve, Pressure Sleeve, Piston Sleeve, Pinion Repair Sleeve, Damper Sleeve, Bore Sleeve, Boost Sleeve

- solenoid, Shift Solenoid, Kickdown Solenoid, Control Solenoid Support, Solenoid Retainer, Interlock Solenoid, Solenoid Switch

- Solenoid Blocks, sol block, Brass Contact,

- EPC, Pressure Solenoid, Pressure Control Solenoid, Pressure Solenoid, PWM solenoid, Pressure Regulator Solenoid

- Solenoid package, solenoids, Solenoid Retainer, Solenoid Kit, pack, Solenoid Upgrade Kit, Solenoid Set, Shift Solenoid Upgrade Kit, Shift Solenoid Kit Set

- TCC sol, tcc solenoid, TCC Reg, TCC PWM

- spragg, Sprags, Mechanical Diode, Sprag Assembly, Sprag Cartridge, One Way Clutches, One Way Clutch, Roller Clutches, Roller Clutch, Low/Rev Diode, Retaining Plates, Retaining Plate, Accordion Spring, OWC

- Springs, Wave Spring, Spring Adjuster, Spring Disc, Torsion Spring, Return Spring, Piston Spring, Damper Spring, Damper Springs, Control Spring, Detent Spring, Drum Spring, Limit Spring, Return Sprng, Diaphragm Springs, Diaphragm Spring

- Stators

- Steel Kits, Steel Set Kit, Steel Clutch Plate Kit, Steel kit, clutch steel, clutch steels, Steel set, steel pack, module kit, Steel Plate Clutch Kit, Steel Plate Kit, Steel Plate Module, Steel Plate Set, Steel Module

- Steel Plates, steel, Steels, steel disk

- Sun Gears, Sungear, Sungears, Sun Gear Retaining Ring, Final Drives, Final Drive, FinalDrive, SUN

- Manifolds, Switch Manifold, Switch Manifolds, Pressure Switch Manifold, Pressure Switch Manifolds, Switch, Manifold

- Washer, Washers, T/Washers, Thrust Washers, Selective Washers, Kit Washer, Drive Sprockets, Driven Sprockets, Drive Sprocket, Thrust Kit, Washer kit,

- Tool kits, Alignments, Alignment, Reamers, Reamer, Tool kit, Tool, Pressure Gauge, Clutch Aligning Tool, Clutch Removal Tool, Clutch Tool Supplement, Kit Installer, Air Test Plate, ADJUSTMENT TOOL, Thread Tap, Remover

- converter, t.converter,

- Throttle Valve, Timing Valve, Operating, Relief Valve, Safety Valve, Control Valve, AFL Valve, Limit Valve, Actuator Feed Limit Valve, AFL Valve

- Overlap Control Valve Kit, Pressure Regulator Valve, Switch Valve Plug, Actuator Feed Limit

Technical issues and repair guidelines

The torque converter, valve body and solenoids in the 4L30E transmission have a relatively limited resource. The operability of these components is gradually deteriorating because of the friction lock-up wear-out and accumulation of varnish in the narrowest places leading to the oil pressure drop and oil starvation, that results in a harmful impact on bushings, which have a proper resource.Operations with the worn-out pump liner and contaminated ATF lead to the oil pump damage. Plastic washer-bearings are also considered to be spare parts to be replaced.

The valve body after 200 thousand kilometers requires a statutory disassembly, repair and cleaning from varnish. The linear pressure solenoid was introduced in the valve body design for the brake band drive gear for regulation of the band pressure on the drum by means of PWM. Solenoids with exhausted resource are considered to be a typical problem in the electrical part of the transmission. The line pressure solenoid is also frequently replaced.

It is a reliable well-regulated transmission with a robust service resource for its components. After a simple overhaul this transmission can additionally operate for several years, if you properly monitor the ATF condition.

Instruction manuals and useful links Suggest your link

| Link type | Source | Description |

|---|---|---|

| www.at-manuals.com | Repair manual 4L30 | |

| www.at-manuals.com | Manual 4L30e | |

| drive.google.com | Repair manual GM Power 4L30e HydraMatic | |

| drive.google.com | Repair manual 4L30E |