U150E Sleeve Transmission parts, repair guidelines, problems, manuals

Transmission general data

| Number of gears | Transmission Type | Drive | ATF (full capacity) L | ATF (change) L | ATF type |

|---|---|---|---|---|---|

| 5 | AT | FWD/AWD | 9 | 4 | Toyota Type T-IV |

What are you looking for?

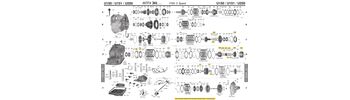

Overhaul Kit | Friction Kit | Friction | Steel Plate | Steel Kit | Band | Solenoid Kit | Solenoid EPC | Solenoid TCC | Pump | Shaft | Drum | Valve body | Torque converter | Hub | Piston | Piston Kit | Planetary Gear | Filter | Gasket | Bushing | Seal | Bearing | Pressure Plate | Stator | Differential | Retainer | Inhibitor Switch | Instruction manual | TOOLS & ACCESORIES | Sensor

Technical issues and repair guidelines

Major repairs of U150-250 units almost always starts with the torque converter repair and spare parts replacement ( lockup).The set of pistons is also included in the typical list of spare parts for repair of this transmission. The pairs of firctions (steel disks in the Overdrive drum) is the first component to get burned in these units. The second spare part to be considered is burnt Direct clutch (happens if the vehicle continuously operates with burnt Overdrive frictions).

The kit of friction components is ordered as frequently as the Overhaul kit especially when repair specialists have to deal with gearboxes with burnt ATF. Early wear of the Overdrive friction clutch is linked to the design of the rear cover, which plays the backup role for this clutch cover (drum). The other common issue for majority of these automated gearboxes is related to problems with pump seals and axles. The pump bushing is usually ordered together with abovementioned spare components. The main symptom of the problem is the ATF leakage through the pump seal. The main cause of this problem is an aggressive driving style and a long-term driving with burnt torque converter clutch.

Electrics in U250-150

Problems with electrical parts in U250 and U151 gearboxes are often triggered by issues with the valve body.The valve body U250 (2002-2004) frequently could not maintain set parameters, old (massive) solenoids couldn’t cope with tasks, therefore the valve body wears rapidly. In 2005, the valve body was updated after replacement of solenoids (the valve body itself was left unchanged). Solenoids for valve bodies of U250 and U151 units ranges for different cars and selected according to VIN-code of the car.

Peculiarities of early repairs of U250 and U151 units are related to the fact that the “electric clutch” was widely used in 2000-th and engineers refused from the "full-proof" comcept and did not limit capacity of the driver related to the aggressive driving style, that may lead to burning of friction components and other elements.

Instruction manuals and useful links Suggest your link

| Link type | Source | Description |

|---|---|---|

| www.at-manuals.com | Repair manual ECT U150E | |

| www.at-manuals.com | Repair manual U150E | |

| www.at-manuals.com | Scheme U150E | |

| www | www.at-manuals.com | Solenoid identification U150E |

| drive.google.com | Repair manual U151E | |

| Sonnax | Valve Body Layout U151E/F, U250E | |

| Sonnax | Vacuum test valvebody U151E/F, U250E |