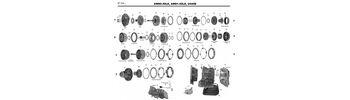

U440E Transmission parts, repair guidelines, problems, manuals

U440F, U441E, AW8040LS, AW8040LE, AW 8140LS, AW8140LE

Transmission general data

| Number of gears | Transmission Type | Drive | Torque (Nm) | ATF (full capacity) L | ATF (change) L | ATF type |

|---|---|---|---|---|---|---|

| 4 | AT | FWD | 150 | 5,8 | 2,1 | Toyota Type T-IV |

The U440E unit was designed by Aisin Co in 1999 for small FWD cars Toyota Yariz, Witz and Corolla with 1.3-liter capacity, which replaced the AW60-40 unit. This gear shifting solution usually can be found on the Japanese market of right-hand drive vehicles. The U340 unit produced simultaneously with U440E was chosen by Toyota for Corolla with the engine capacity of 1.5 liters and higher. The U540E unit more known as AQ4 is a quite rare solution for Daihatsu with more simple complete set. This gearbox is also used for American small cars Cadillac, Buick, Ford and Chinese Donfeng, Landwind under names AW80-40LS and AW81-40LS.

The U440E unit was designed by Aisin Co in 1999 for small FWD cars Toyota Yariz, Witz and Corolla with 1.3-liter capacity, which replaced the AW60-40 unit. This gear shifting solution usually can be found on the Japanese market of right-hand drive vehicles. The U340 unit produced simultaneously with U440E was chosen by Toyota for Corolla with the engine capacity of 1.5 liters and higher. The U540E unit more known as AQ4 is a quite rare solution for Daihatsu with more simple complete set. This gearbox is also used for American small cars Cadillac, Buick, Ford and Chinese Donfeng, Landwind under names AW80-40LS and AW81-40LS.

What are you looking for?

Overhaul Kit | Friction Kit | Friction | Steel Plate | Steel Kit | Band | Solenoid Kit | Solenoid EPC | Solenoid TCC | Pump | Shaft | Drum | Valve body | Torque converter | Hub | Piston | Piston Kit | Planetary Gear | Filter | Gasket | Bushing | Seal | Bearing | Pressure Plate | Stator | Differential | Retainer | Inhibitor Switch | Instruction manual | TOOLS & ACCESORIES | Sensor

Which cars run with this gearbox?

| Brand | Model | Year | Type | Engine |

|---|---|---|---|---|

| Beijingauto | E-SERIES | 12-16 | 4 SP FWD | L4 1.3L 1.5L |

| Buick | EXCELLE/EXCELLE HRV | 03-12 | 4 SP FWD | L4 1.6L 1.8L |

| Changan | CD101 | 12 | 4 SP FWD | L4 2.0L |

| Changan | CX20 | 10-16 | 4 SP FWD | L4 1.3L |

| Changan | JOICE | 07-12 | 4 SP FWD | L4 1.6L 2.0L |

| Changan | V805 | 10-12 | 4 SP FWD | L4 1.6L |

| Changan | YUEXIANG | 09-14 | 4 SP FWD | L4 1.5L |

| Changan | YUEXIANG V5 | 12-16 | 4 SP FWD | L4 1.5L |

| Changan | Z-SHINE | 08-12 | 4 SP FWD | L4 1.5L 1.6L 1.8L 2.0L |

| Chevrolet/GM | AVEO | 06-16 | 4 SP FWD | L4 1.4L |

| Chevrolet/GM | AVEO | 09-16 | 4 SP FWD | L4 1.6L |

| Chevrolet/GM | CRUZE | 01-08 | 4 SP FWD | L4 1.3L |

| Chevrolet/GM | LOVA | 06-11 | 4 SP FWD | L4 1.4L 1.6L |

| Chevrolet/GM | VIVA | 11 | 4 SP FWD | L4 1.4L |

| Daewoo | GENTRA | 05-16 | 4 SP FWD | L4 1.4L 1.5L 1.6L |

| Daewoo | GENTRA | 07-16 | 4 SP FWD | L4 1.2L |

| Daewoo | KALOS | 02-08 | 4 SP FWD | L4 1.2L 1.4L 1.5L 1.6L |

| Daewoo | LACETTI | 02-10 | 4 SP FWD | L4 1.4L 1.5L 1.6L |

| Dongfeng | A30 | 14-16 | 4 SP FWD | L4 1.5L |

| Dongfeng | BFX | 11 | 4 SP FWD | L4 1.6L |

| Dongfeng | H30 | 10-16 | 4 SP FWD | L4 1.5L 1.6L |

| Dongfeng | JOYEAR | 16 | 4 SP FWD | L4 1.5L |

| Dongfeng | S30 | 09-16 | 4 SP FWD | L4 1.5L 1.6L |

| FAW | OLEY | 12-16 | 4 SP FWD | L4 1.5L |

| Ford | FIESTA | 97-16 | 4 SP FWD | L4 1.6L |

| Ford | FUSION | 06-12 | 4 SP F/4WD | L4 1.6L |

| Gonow | E MEI | 14-16 | 4 SP FWD | L4 1.6L |

| Land-Wind | B102 HB / B103 NB | 11-12 | 4 SP FWD | L4 1.6L |

| Land-Wind | E101 | 11-12 | 4 SP FWD | L4 2.0L |

| Land-Wind | FENGSHANG | 06-10 | 4 SP FWD | L4 2.0L |

| MG | 5 | 12-16 | 4 SP FWD | L4 1.5L |

| Opel / Vauxhall | AGILA | 08-14 | 4 SP FWD | L3 1.0L L4 1.2L |

| Roewe | 350 | 10-16 | 4 SP FWD | L4 1.5L |

| Scion | XA | 03-07 | 4 SP FWD | L4 1.5L |

| Scion | XB | 03-07 | 4 SP FWD | L4 1.5L |

| Suzuki | ALTO | 09-15 | 4 SP FWD | L3 1.0L |

| Suzuki | ALTO | 15-16 | 4 SP FWD | L3 1.0L |

| Suzuki | BALENO | 00-08 | 4 SP FWD | L4 1.5L |

| Suzuki | SPLASH | 08-14 | 4 SP FWD | L4 1.2L |

| Suzuki | SWIFT | 97-16 | 4 SP FWD | L4 1.2L 1.3L 1.4L 1.5L 1.6L |

| Suzuki | SX4 SPORTY | 07-14 | 4 SP FWD | L4 1.5L |

| Suzuki | SX4 SUV | 06-14 | 4 SP F/4WD | L4 1.5L 1.6L |

| Suzuki | SX4 SUV | 06-14 | 4 SP FWD | L4 1.6L |

| Suzuki | WAGON R | 00-11 | 4 SP F/4WD | L4 1.0L 1.3L |

| Toyota | BB | 00-05 | 4 SP F/4WD | L4 1.3L 1.5L |

| Toyota | BELTA | 06-16 | 4 SP F/4WD | L4 1.3L |

| Toyota | COROLLA | 00-07 | 4 SP FWD | L4 1.3L |

| Toyota | ETIOS | 13 | 4 SP FWD | L4 1.3L |

| Toyota | FUNCARGO | 00-05 | 4 SP FWD | L4 1.3L |

| Toyota | IST | 02-07 | 4 SP F/4WD | L4 1.3L 1.5L |

| Toyota | PLATZ | 02-05 | 4 SP F/4WD | L4 1.0L 1.3L |

| Toyota | PORTE | 04-12 | 4 SP FWD | L4 1.3L |

| Toyota | PROBOX | 02-16 | 4 SP FWD | L4 1.3L |

| Toyota | TERCEL | 00-03 | 4 SP FWD | L4 1.3L 1.5L |

| Toyota | VIOS | 03-16 | 4 SP FWD | L4 1.3L |

| Toyota | VITZ | 11-16 | 4 SP FWD | L4 1.3L 1.5L |

| Toyota | WILL CYPHA / VI / VS | 00-05 | 4 SP F/4WD | L4 1.3L 1.5L |

| Toyota | YARIS | 01-12 | 4 SP FWD | L4 1.3L 1.5L |

| Toyota | YARIS | 12-13 | 4 SP FWD | L4 1.5L |

| Toyota | YARIS L | 14-16 | 4 SP FWD | L4 1.3L |

Technical issues and repair guidelines

The repair of this transmission is usually performed for cars with high mileage and already worn-out torque converter lockup unit. Each 4-th case of the rebuilding of this robust unit requires MasterKit – complete kit of spare parts. After the exhaustion of resource of this transmission (and rings wear-out), the first component to be worn is a set of frictions with steel discs in the clutch package Direct. After that, С1 Forward and Overdrive frictions get worn and then others.

The "soft spot" of AW81-40 components is considered to be the planetary gear, which even during testing required some servicing before covering 100 thousand kilometers. The reason is related to design issues. The transmission of maximum operating torque via the gear to the differential by means of strong side loads leads to the damage of units in this package. (Only paired with 1.6 liter engines). The major wear-out of friction units and consequent damage of the pump bushing takes place when neglecting the oil pressure parameters and wear-out of the torque converter.

As for electrical components, standard cleaning and valve body reassembly, repair specialists order EPC and On-Off solenoids. Sometimes the differential is also ordered for the overhaul. In old cars, specialist often install external fine filter. The filter helps to preserve clean ATF and decreases wear-out of friction components.

The spare parts resource will be significantly increased, if ATF is kept clean and the torque converter gets repaired after covering 150- 200 thousand kilometers (depending on the car type and driving style) and preventive cleaning of the valve body and solenoids. More often problems occur in cars with engines capacity equal to 1.3. The torque of these engines turns out to be too high for this automatic unit and electronic control allows the driver to load the transmission to the maximum. Careful usage of cars with this gearbox without fast accelerations from traffic lights and slipping on deep snow allows postponing first overhauls of this “invincible” gearbox for 6 or more years.

Instruction manuals and useful links Suggest your link

| Link type | Source | Description |

|---|---|---|

| www.at-manuals.com | Scheme U440E | |

| www | www.at-manuals.com | Check Balls U440E |

| www | www.at-manuals.com | Stall test U440E |